غراء الخشب مع المصلب - قوة ربط فائقة ومتانة تدوم طويلاً!

إذا كنت تبحث عن رابطة قوية للغاية ومتينة للخشب، تتجاوز قوة الغراء الأبيض التقليدي، فإن غراء الخشب مع المصلب (Wood Glue with Hardener) هو الحل الأمثل. يُعرف هذا النوع من الغراء بقدرته على تكوين رابطة كيميائية قوية جدًا مع ألياف الخشب، مما يجعله مثاليًا للتطبيقات التي تتطلب قوة تحمل عالية، مقاومة للماء، وعمرًا طويلاً.

ما هو غراء الخشب مع المصلب؟ وكيف يعمل؟

غراء الخشب مع المصلب هو في الأساس نظام مكون من جزأين:

- الغراء الأساسي: وهو عادةً غراء راتنج يوريا فورمالدهايد (Urea-Formaldehyde Resin Glue) أو أنواع أخرى من الراتنجات التفاعلية.

- المصلب (Hardener/Catalyst): عبارة عن بودرة أو سائل حمضي أو قاعدي يُضاف إلى الغراء الأساسي قبل الاستخدام مباشرة.

كيف يعمل: عند خلط المصلب مع الغراء الأساسي، تبدأ عملية تفاعل كيميائي تُعرف بالبلمرة. هذا التفاعل يتسبب في تحول الغراء من سائل إلى مادة صلبة شديدة المقاومة، مما يخلق رابطة قوية جدًا ومقاومة للماء والرطوبة، وأحيانًا للحرارة، بشكل يفوق قدرة الغراء العادي.

لماذا تختار غراء الخشب مع المصلب؟ وما هي استخداماته؟

- قوة ربط فائقة: يوفر أقوى أنواع الروابط الممكنة للخشب، غالبًا ما تكون أقوى من الخشب نفسه. هذا يجعله مثاليًا للتطبيقات الهيكلية أو التي تتعرض لإجهاد عالٍ.

- مقاومة عالية للماء والرطوبة: على عكس معظم أنواع الغراء الأبيض (PVA) التي تضعف بالرطوبة، يتميز غراء الخشب مع المصلب بمقاومة ممتازة للماء، مما يجعله مناسبًا للاستخدام في:

- الأثاث الخارجي.

- أجزاء المطبخ والحمام المعرضة للرطوبة.

- القوارب والأعمال الخشبية البحرية.

- الأرضيات الخشبية.

- ثبات في الأبعاد: يساعد على منع التواء أو تشوه الخشب في نقاط التجميع.

- مناسب لأنواع مختلفة من الخشب: يعمل بفعالية على الخشب الصلب، الخشب اللين، الألواح الخشبية المصنعة (مثل الـ MDF والتشيبورد)، والقشرة الخشبية.

- استخدامات متعددة:

- تصنيع الأثاث عالي الجودة والمتين.

- تجميع الأبواب والنوافذ الخشبية.

- إصلاح الأثاث التالف بشكل كبير.

- تطبيقات النجارة التي تتطلب قوة تحمل استثنائية.

اعتبارات هامة عند استخدام غراء الخشب مع المصلب:

- التحضير الدقيق للخليط: اتبع تعليمات الشركة المصنعة بدقة لنسبة خلط الغراء والمصلب. أي خطأ في النسبة قد يؤثر على قوة الرابطة ووقت التجفيف.

- وقت العمل (Pot Life): بمجرد خلط المكونين، يبدأ التفاعل الكيميائي. لكل نوع غراء "وقت عمل" محدد (Pot Life)، وهو الفترة التي يبقى فيها الغراء قابلاً للاستخدام قبل أن يبدأ في التصلب. جهز الكمية التي يمكنك استخدامها خلال هذا الوقت فقط.

- التهوية الجيدة: بعض أنواع هذه المواد قد تصدر أبخرة. تأكد من العمل في منطقة جيدة التهوية.

- الضغط (Clamping): يتطلب هذا النوع من الغراء ضغطًا جيدًا ومستمرًا (بالمشابك) أثناء عملية التجفيف لضمان أقصى قوة للرابطة.

- وقت التجفيف: يختلف وقت التجفيف بناءً على نوع الغراء، نسبة الخلط، درجة الحرارة، والرطوبة. التزم بالوقت الموصى به قبل فك المشابك أو تحميل الوصلة.

- التنظيف: نظف أي بقايا غراء زائدة فورًا بعد التجميع قبل أن يتصلب، باستخدام الماء أو مذيب مناسب حسب نوع الغراء.

لضمان أفضل النتائج والمتانة في مشاريعك الخشبية، يُعد غراء الخشب مع المصلب هو الاختيار الاحترافي الذي يوفر لك رابطة لا مثيل لها وقوة تدوم طويلاً.

استفسارات المنتج (0)

تسجيل الدخول أو سجل الآنلكي تتمكن من التواصل مع خدمة المبيعات مباشرة

أسئلة أخري ؟

لا توجد اسئلة اخري ، لا تتردد في التواصل مع فريق المبيعات لمساعدتك !

منتجات يم شراؤها معًا

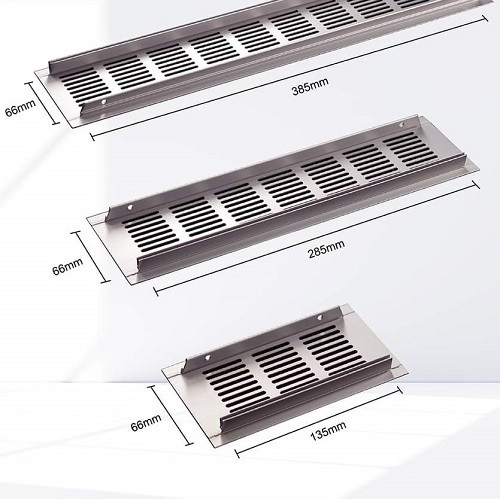

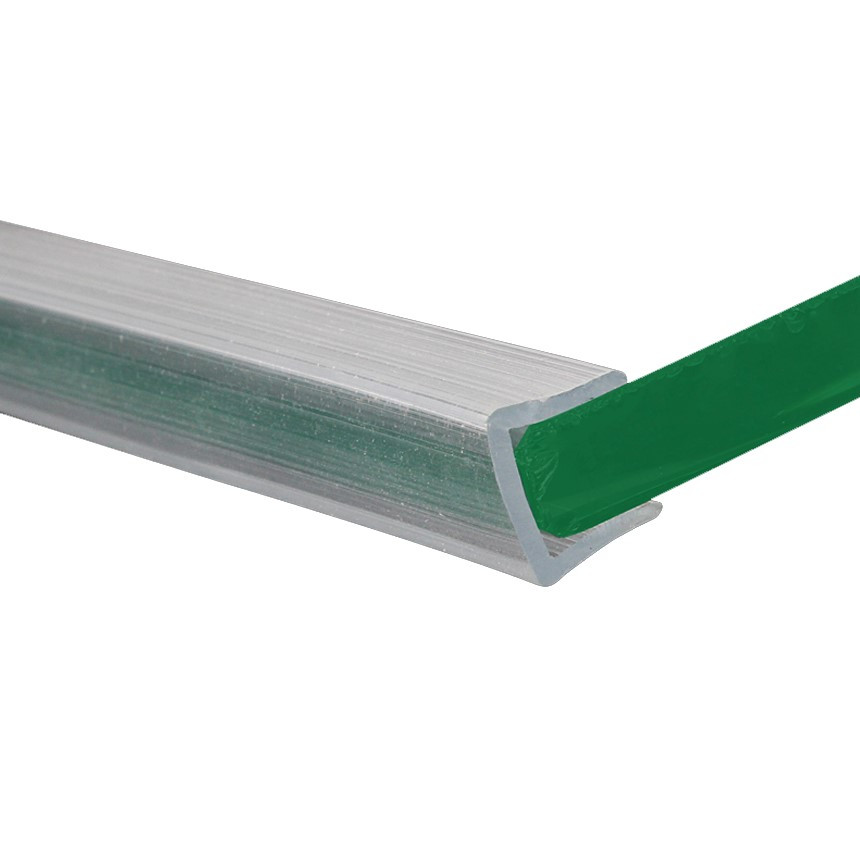

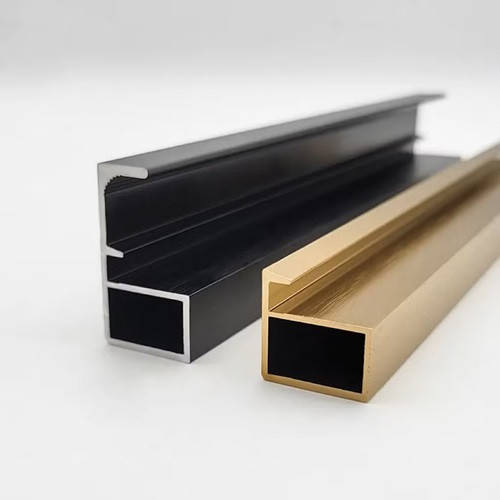

ربر شفاف حرف U

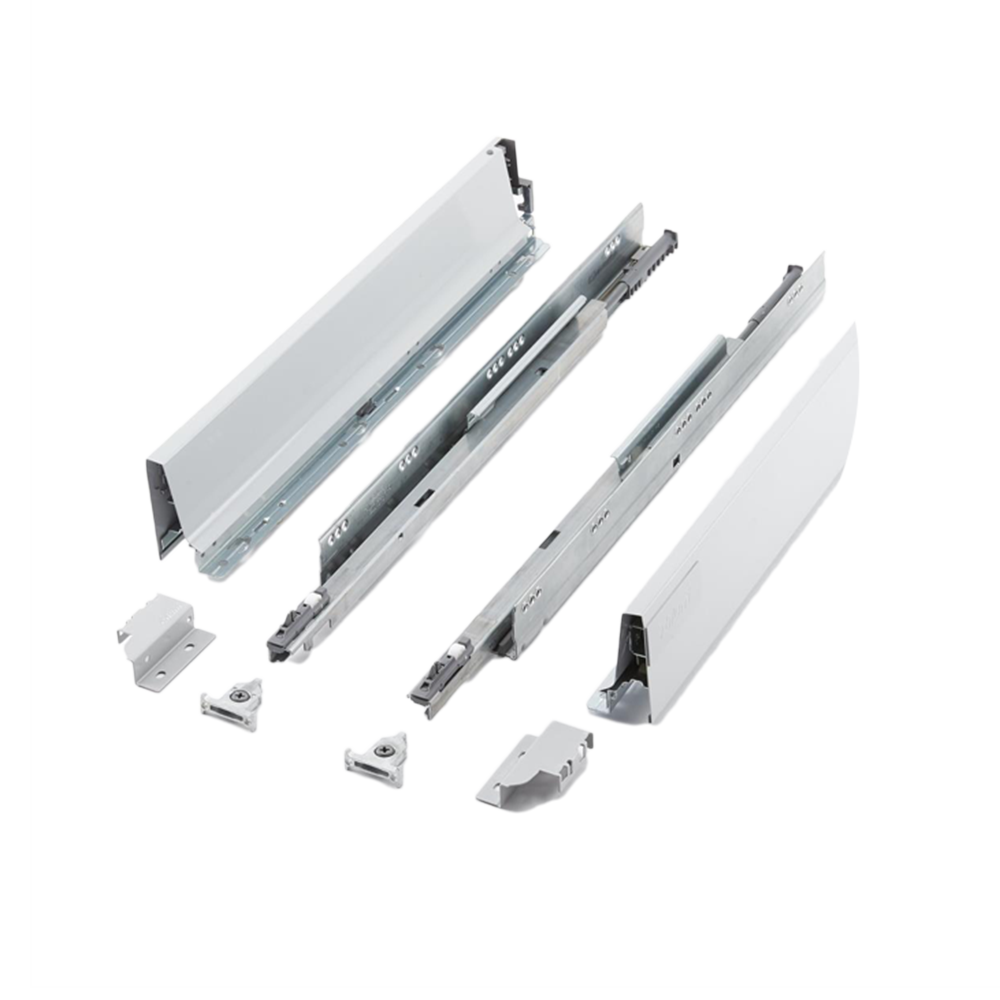

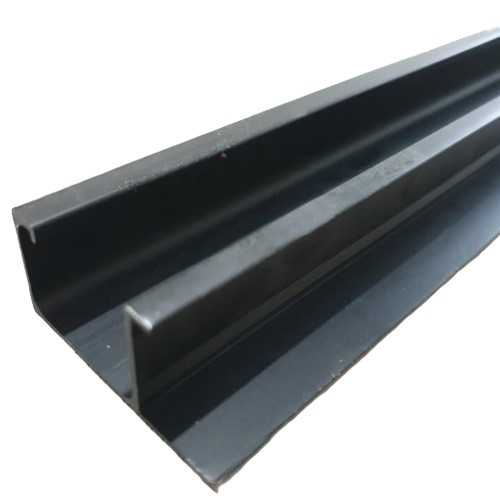

مجرى درج سوفت كلوز

ماسوره بيضاوى تعليق ملابس 3م

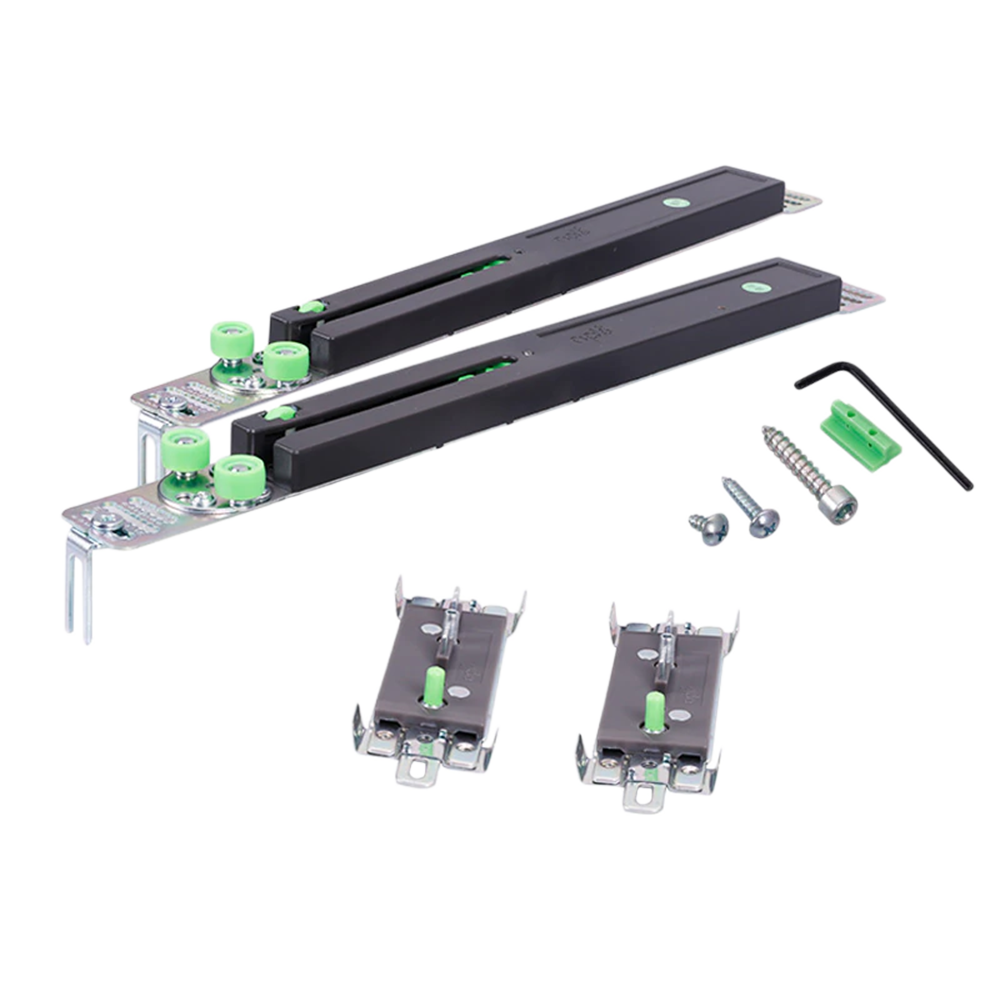

مجرى درج سفلي تاتش وود

ماسورة نيكل دائري 3م

رداد خارجي كبير

منتجات اكتر من تاتش وود

اظهـر الكل

Share with Friends

Trading is more effective when you share products with friends!Share you link

Share to