تجميع ميني فيكس, اليته تجميع

تجميع الميني فيكس: آلية خفية وقوية لأثاثك

العنوان: تجميع الميني فيكس: آلية مخفية، سهولة تجميع، ومتانة عالية لأثاثك في السعودية

الوصف التعريفي (Meta Description): تعرف على آلية تجميع الميني فيكس، نظام التثبيت المفضل للأثاث الجاهز (Flat-Pack). يوفر وصلات قوية وغير مرئية، يسهل التفكيك وإعادة التركيب، ويمنح الأثاث مظهرًا احترافيًا.

الوصف التفصيلي:

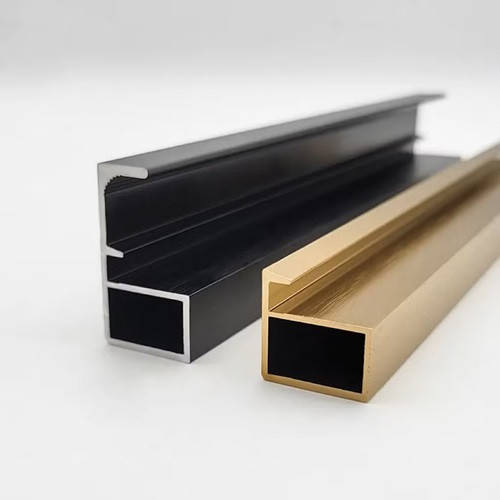

إذا كنت تتساءل عن كيفية تجميع قطع الأثاث التي تصلك مفككة (Flat-Pack Furniture) بطريقة تبدو وكأنها قطعة واحدة متكاملة، فإن نظام الميني فيكس (Minifix) هو الإجابة! يُعد الميني فيكس أحد أشهر وأكثر أنظمة التجميع المخفية استخدامًا في صناعة الأثاث الحديث، وذلك بفضل جمعه بين القوة، الجمالية، وسهولة الاستخدام.

ما هو نظام الميني فيكس؟

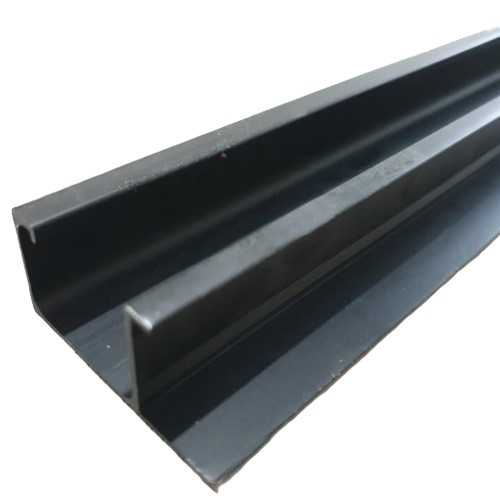

الميني فيكس هو نظام تجميع يتكون عادةً من ثلاثة مكونات رئيسية تعمل معًا لربط لوحين خشبيين (مثل لوح جانبي مع لوح رف أو قاعدة) بزاوية قائمة، دون أن تظهر أي مسامير أو براغي من الخارج. هذه المكونات هي:

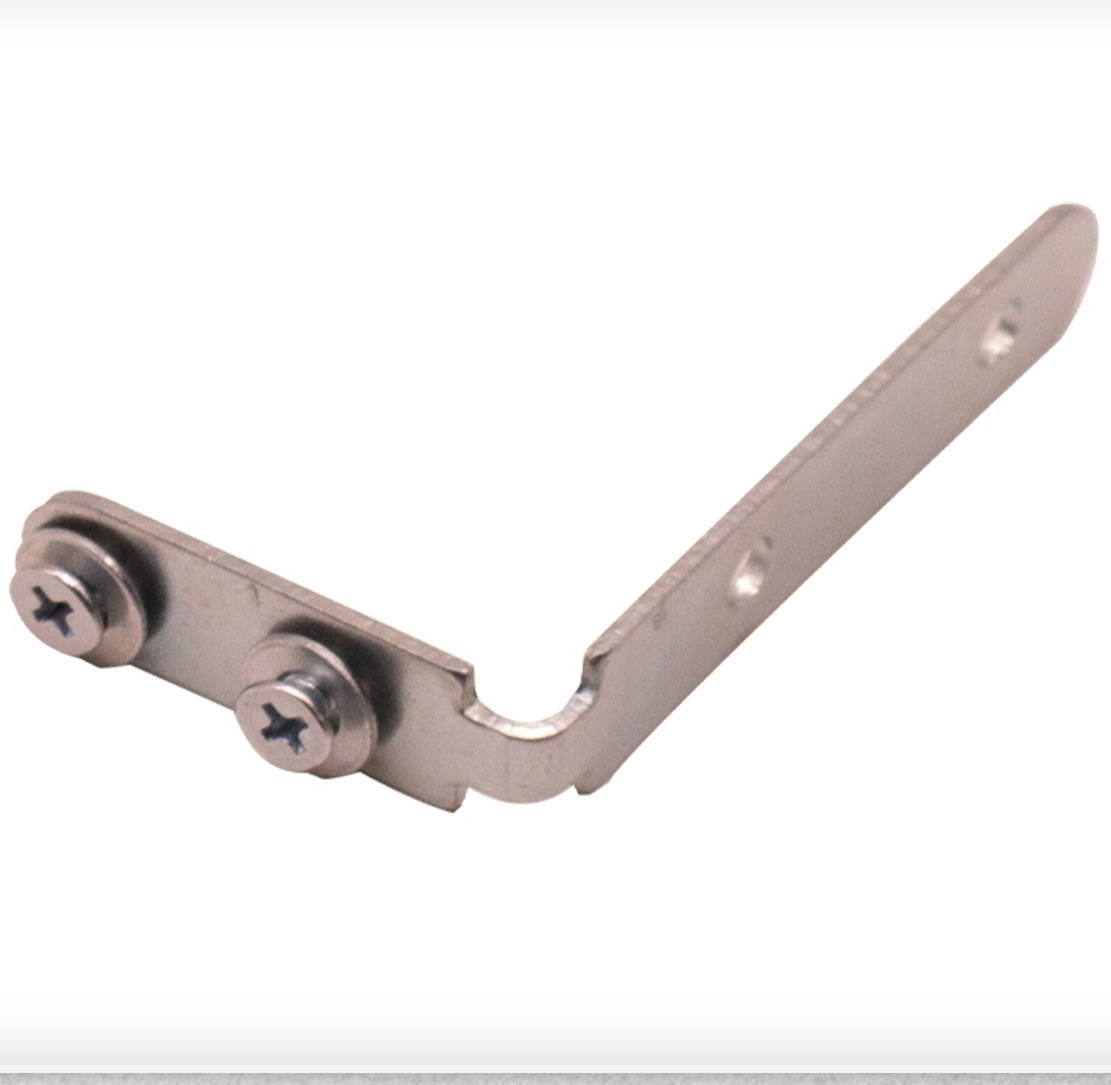

- برغي التوصيل (Connecting Bolt / Dowel Screw): وهو برغي معدني ذو رأس خاص. يتم تثبيته مسبقًا في حافة اللوح الذي سيتم توصيله (مثل لوح الرف).

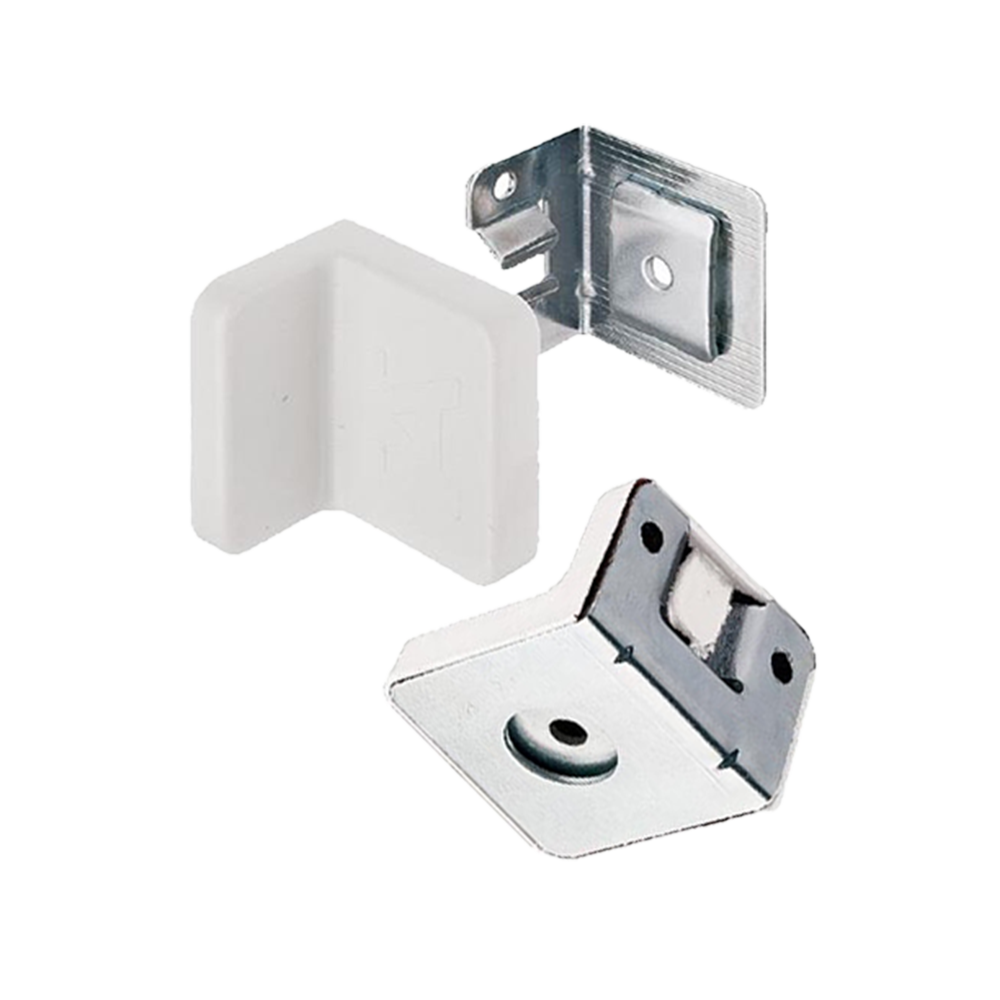

- جلبة/دعامة (Dowel / Bushing): وهي قطعة بلاستيكية أو معدنية أسطوانية تُدخل في ثقب مُجهز مسبقًا في اللوح الثاني (مثل اللوح الجانبي). يمر برغي التوصيل من خلالها.

- الكامة (Cam / Minifix Housing): وهي قطعة معدنية (غالباً من سبائك الزنك) دائرية الشكل، تحتوي على فتحة غير مركزية (على شكل هلال أو بيضاوي) وشق لدفعها بمفك براغي (عادةً فيليبس). تُدخل الكامة في ثقب كبير ومُجهز مسبقًا في السطح الخارجي للوح الثاني (الجانبي).

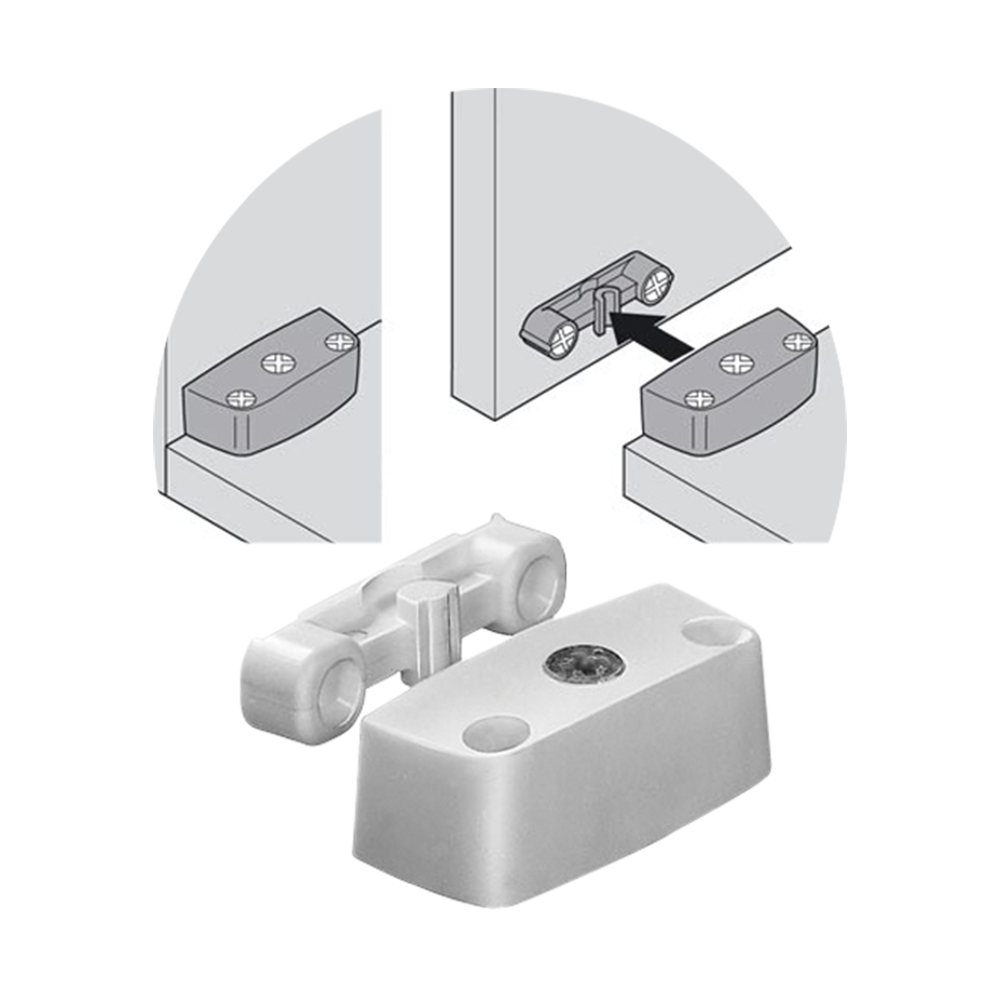

كيف تعمل آلية التجميع (التركيب)؟

آلية عمل الميني فيكس بسيطة وفعالة، وتتم على عدة خطوات:

- تحضير الألواح: يتم حفر ثقوب مخصصة لكل مكون من مكونات الميني فيكس في الألواح الخشبية مسبقًا في المصنع.

- للوح الأول (مثلاً، الرف): يُحفر ثقب على الحافة لإدخال برغي التوصيل.

- للوح الثاني (مثلاً، الجانب): يُحفر ثقبان: أحدهما في الحافة لاستقبال طرف برغي التوصيل، والآخر (الأكبر) في السطح الخارجي (المرئي) لاستقبال الكامة.

- تثبيت برغي التوصيل: يُلصق أو يُشد برغي التوصيل في الثقب المخصص له على حافة اللوح الأول (الرف).

- إدخال الجلبة (اختياري): في بعض أنواع الميني فيكس، تُدخل جلبة بلاستيكية في الثقب المقابل في اللوح الثاني (الجانبي) لضمان محاذاة أفضل وزيادة قوة التثبيت.

- تجميع الألواح: يتم وضع اللوح الأول (الرف) في مكانه بحيث يدخل برغي التوصيل الخاص به في الثقب المخصص له في اللوح الثاني (الجانب).

- تثبيت الكامة: تُدخل الكامة في الثقب الكبير الموجود على السطح الخارجي للوح الثاني، بحيث يكون طرف برغي التوصيل داخل فتحة الكامة.

- إحكام الربط: باستخدام مفك براغي (فيليبس أو سداسي داخلي)، يتم تدوير الكامة بزاوية 180 درجة (عادةً حتى يتوقف). أثناء الدوران، تقوم الفتحة غير المركزية في الكامة بسحب برغي التوصيل إلى الداخل بإحكام، مما يؤدي إلى سحب اللوحين معًا بقوة شديدة وإنشاء وصلة صلبة ومحكمة.

مميزات تجميع الميني فيكس:

- وصلة مخفية: لا تظهر أي أدوات تثبيت من الخارج، مما يعطي الأثاث مظهرًا نظيفًا، أنيقًا، واحترافيًا.

- سهولة التجميع والتفكيك: يمكن تجميع الأثاث وتفكيكه بسهولة عدة مرات دون إلحاق الضرر بالألواح، مما يجعله مثاليًا للأثاث الذي يحتاج إلى النقل أو إعادة الترتيب.

- قوة ومتانة: يوفر تثبيتًا قويًا وموثوقًا به، ويوزع الحمل بفعالية، مما يزيد من عمر الأثاث.

- دقة في المحاذاة: يساعد التصميم الدقيق للميني فيكس في تحقيق محاذاة مثالية بين الألواح، مما يقلل من الفجوات ويضمن استواء السطوح.

- مثالي للأثاث الجاهز (Flat-Pack): يُسهل عملية التجميع للمستهلكين، حيث لا يتطلب أدوات خاصة معقدة أو خبرة كبيرة في النجارة.

بشكل عام، يُعد الميني فيكس حلاً ذكيًا وعصريًا لتجميع الأثاث، يجمع بين الجمالية الخفية والقوة العملية.

استفسارات المنتج (0)

تسجيل الدخول أو سجل الآنلكي تتمكن من التواصل مع خدمة المبيعات مباشرة

أسئلة أخري ؟

لا توجد اسئلة اخري ، لا تتردد في التواصل مع فريق المبيعات لمساعدتك !

منتجات يم شراؤها معًا

تجميع رف مجنح

زاويه تجميع فراشة معدنية

مينى فكس دائرى للأرفف

زاويه تجميع هرم منفصل

زاوية تجميع معدن 3d

مجابد تجميع

منتجات اكتر من تاتش وود

اظهـر الكل

Share with Friends

Trading is more effective when you share products with friends!Share you link

Share to